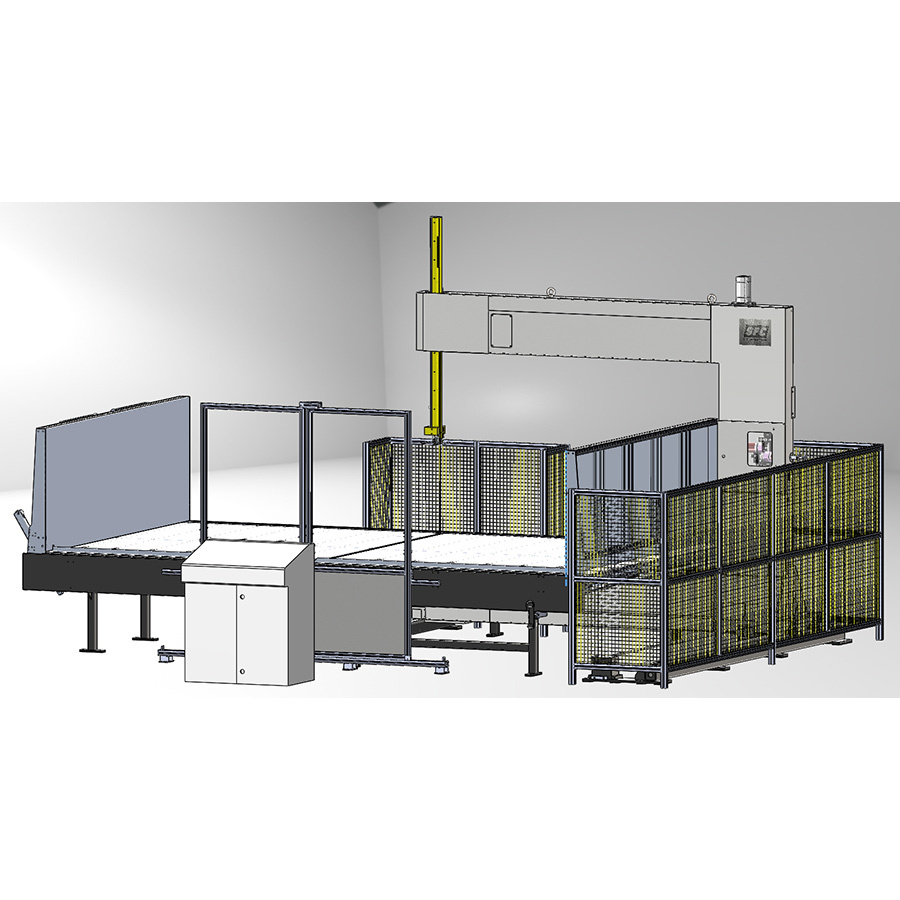

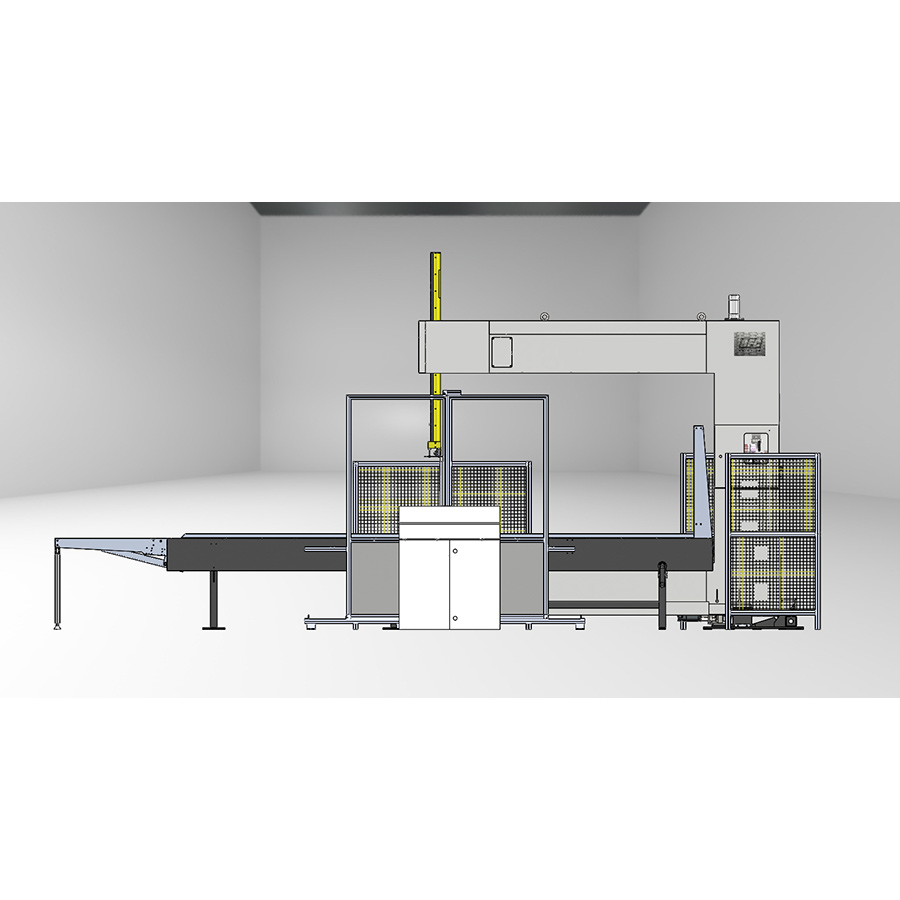

SFC – V1 AUTOMATIC VERTICAL CUTTING MACHINE

Fully Automatic Vertical cutting machine for cutting foam blocks. It cuts with very high precision in high quality standards with its movable cutting unit and fixed table.

Technical Specifications

|

CUTTING DIMENSIONS |

STANDARD |

OPTIONAL |

|

Table Width |

2250mm |

2500mm |

|

Table Length |

2250mm |

2500mm-3000mm |

|

Height |

1300mm |

1400mm |

|

SIDE STOP PLATES DIMENSIONS |

STANDARD |

OPTIONAL |

|

Right Height |

1000mm |

1200mm |

|

Left Height |

1000mm |

1200mm |

Features

Very High Speed and Low Vibration

The cutting blade cuts in high accuracy with its guided by linear guides. Low vibration and low noise driven by last generation servo motors.

Fixes the Material Properly

It is driven by a belt system for precise positioning of the side tables.

Correct Positioning of the Foam Block

With the side tables, the foam block is fixed, and the correct cutting position is adjusted.

Sharpening System

Automatic sharpening is optional.

High speed cut times

Required cutting length input is avalible to reduce cutting times to minimum

Machine Usage and Lifecycle

With high quality components, machine has a long lifetime and very low maintenance requirements.

Ensuring the Best Cut Results

Safe and stable cutting results are obtained with the blade guide system on the cutting tower.

Easy and Comfortable Operation

Convenient control panel and interface make it easy for the operator.

Exact Cutting Results

Quality Standard

The machine is manufactured according to European standards and has CE certification.

CUTTING PROPERTIES

The cutting speed can be adjusted between 5 – 60 m/min.

Cutting precision: ±0,1 mm

Minimum cut thickness: 3 mm

Blade dimensions 10380x10x0,45 mm

Flexible PU foam (Polyester and Polyether), Rebonded, Viscoelastic, Latex etc. materials can be cut.

STANDART PROPERTIES

Sharpening Unıt

Automatic time defined grinding system with stable and powerful motor driven Sharpening Unıt.

Spark Extraction Unit

Cooled filter system that absorbs and removes dust and sparks generated during sharpening.

Pneumatic Blade Tensioning System

Anodized Coated Aluminum Table Surface

Siemens Command and Control Unit

Siemens Servo Motor Controlled Axes

Shock Absorber Supported Extendable Plate makes loading and unloading of foam much easier and comfortable.

Safety Gate and Security Barriers can be opened.

Impact Safe, Height Adjustable Blade Guide System

Siemens Servo Motor Controlled Axes

English and German Interface Option

OPTIONAL PROPERTIES

Blower System

Blower system option for easy movement of heavy blocks on the table.

Sharpening Quality Monitoring System

It enables the quality of knife sharpening to be monitored with illumination and lens method.

Cut-by-Cut Speed Control System

It enables the best quality cutting with the recipes prepared according to the product to be cut.

Automatic Sharpening Feature Without the Operator

With the pneumatic system, the sharpening time and sharpening time range can be adjusted.