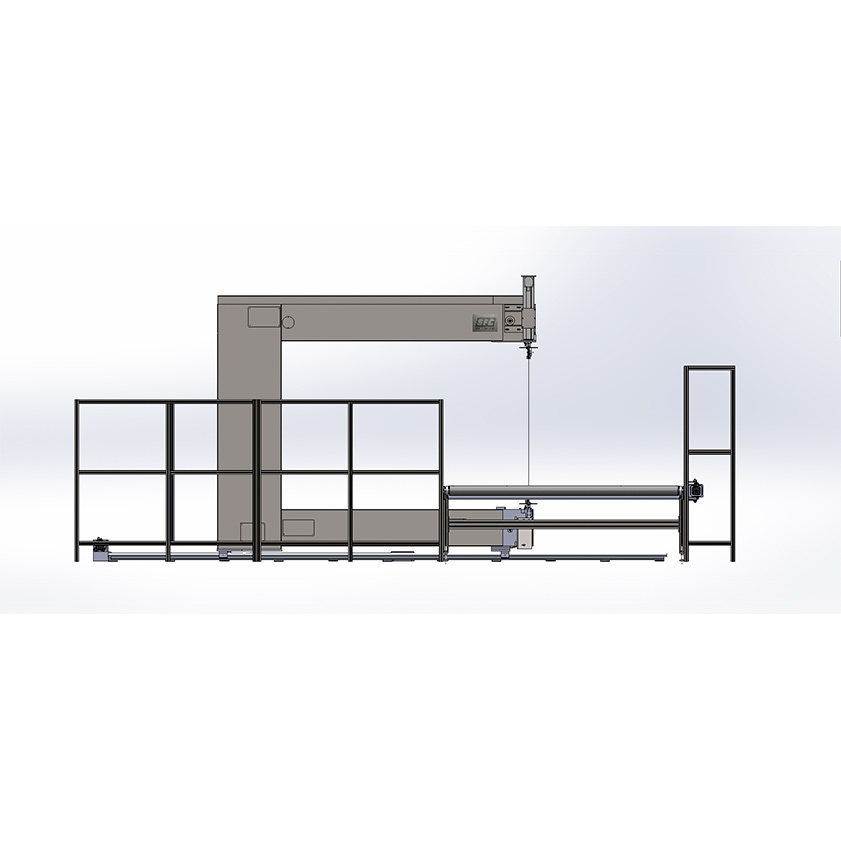

SFC – V2 AUTOMATIC VERTICAL TRIMMING MACINE

Multi function block cutting muchine used for cutting short blocks from long foam buns as well as trimming side skins and making multiple dimentional cuts via 90 degress rotating knife.

Technical Specifications

|

CUTTING DIMENSIONS |

STANDARD |

OPTIONAL |

|

Table Width |

2500mm |

- |

|

Height |

1350mm |

1500mm |

|

Block Slitting Length |

3500mm |

4500mm |

Features

Quailty Standard

The machine is manufactured according to European standards and has CE certification.

CUTTING PROPERTIES

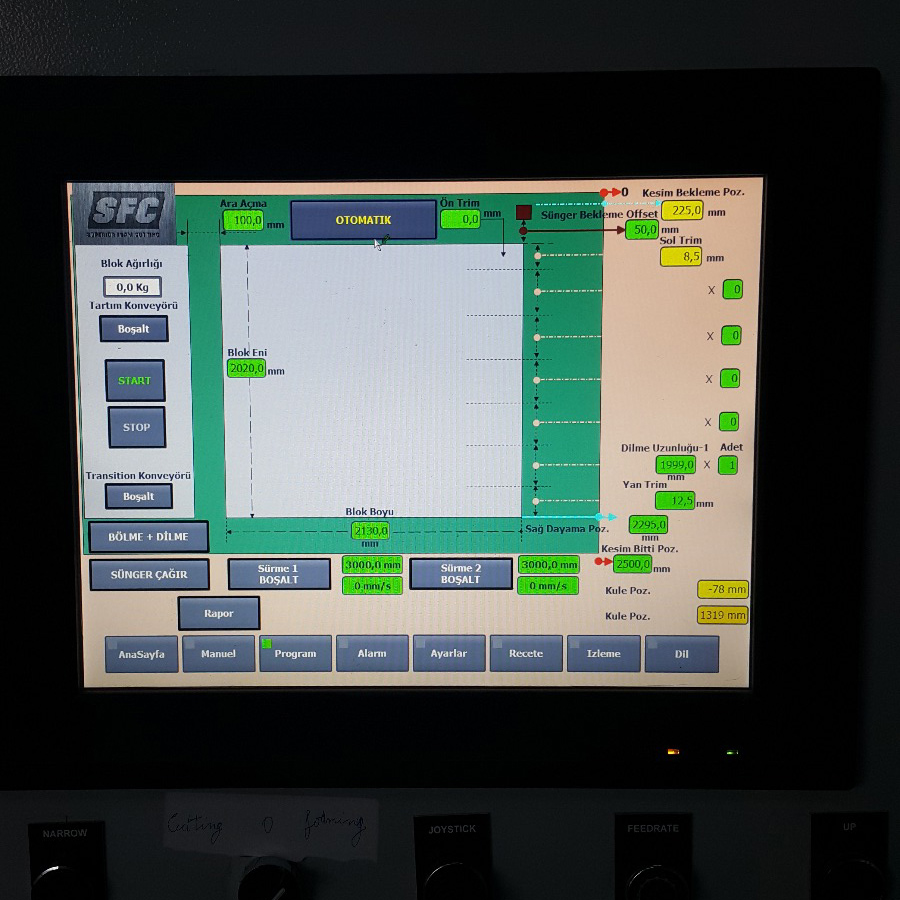

The cutting speed can be adjusted between 2 – 30 m/min. 2 – 40 m/min optional.

The cutting precision: ±2 mm

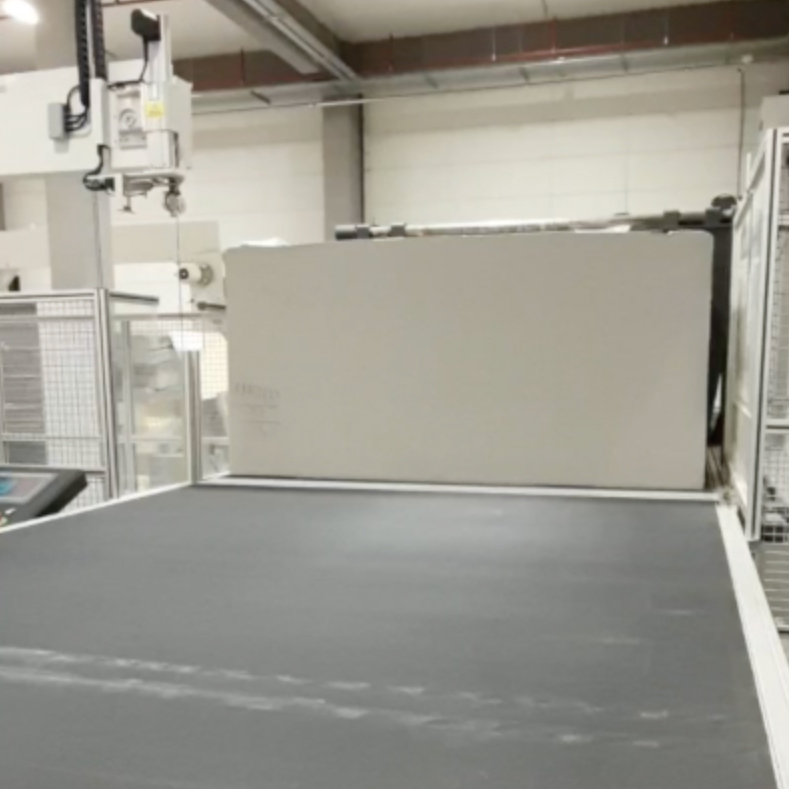

Flexible PU foam (Polyester and Polyether), Rebonded, Viscoelastic, Latex etc. materials can be cut.

STANDART PROPERTIES

Different Working Modes

The block to be cut has a system infrastructure that can perform dividing, slitting and edge trimming operations on both axes on a Windows-based computer screen, manually, semi-automatically and automatically by calculating all wastages at the optimum level.

Sharpening Unıt

Efficient semi-automatic grinding system with stable and powerful motor driven Sharpening Unıt.

The automatic griding system is optional, depending on the preference.

Blade Guidance System

It is a height-adjustable position-controlled guidance system that guides the blade from multiple points with an electric actuator motor to provide precise cutting for high density blocks.

Spark Extraction Unit

Cooled filter system that absorbs and removes dust and sparks generated during sharpening.

Pneumatic Blade Tensioning System

Siemens Control and Control Unit

Siemens Servo Engine controlled Axes

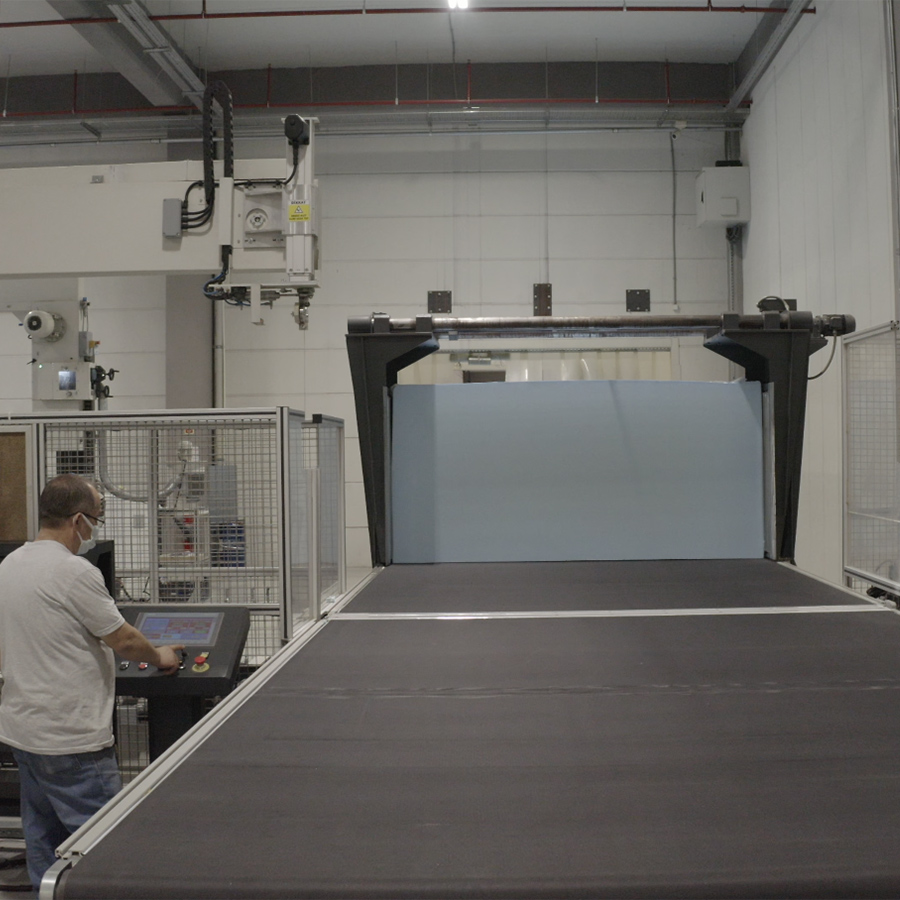

Deployable Safety Gate and Safety barriers

Stabbing Safe Blade Guide

Conveyor tapes with Guidance System

English and German Interface Option

Panel Type Air Conditioning System

It is used for cooling the electrical panel for locations with high ambient conditions.

Sharpening Quality Monitoring System

It enables the quality of knife sharpening to be monitored with illumination and lens method.

Block Centering System

It is the system that allows the block to be positioned precisely. It is a roll guidance system with a length of 2000 mm on both sides of the block. It has a maximum operating range of 2600 mm with a minimum of 1250 mm.